Description:

The production process of flushable spunlace nonwoven fabrics is to mix viscose staple fibers and wood pulp fibers into a suspension, and then form fiber wet paper through a large amount of dehydration during the web-forming process. Then, these wet papers are reinforced by a spunlace machine, and finally dehydrated and dried to form a flushable nonwoven fabric.

The main components of this non-woven fabric are viscose and wood pulp, both of which are degradable cellulose fibers and conform to the concept of environmental protection. The flushable property effectively reduces the generation of solid waste and makes it more convenient to use. At present, this flushable non-woven fabric has been widely used in a variety of hygiene products such as wet toilet paper, baby wipes, disinfectant wipes, makeup remover wipes, etc., meeting consumers' needs for environmental protection and convenience.

Specification:

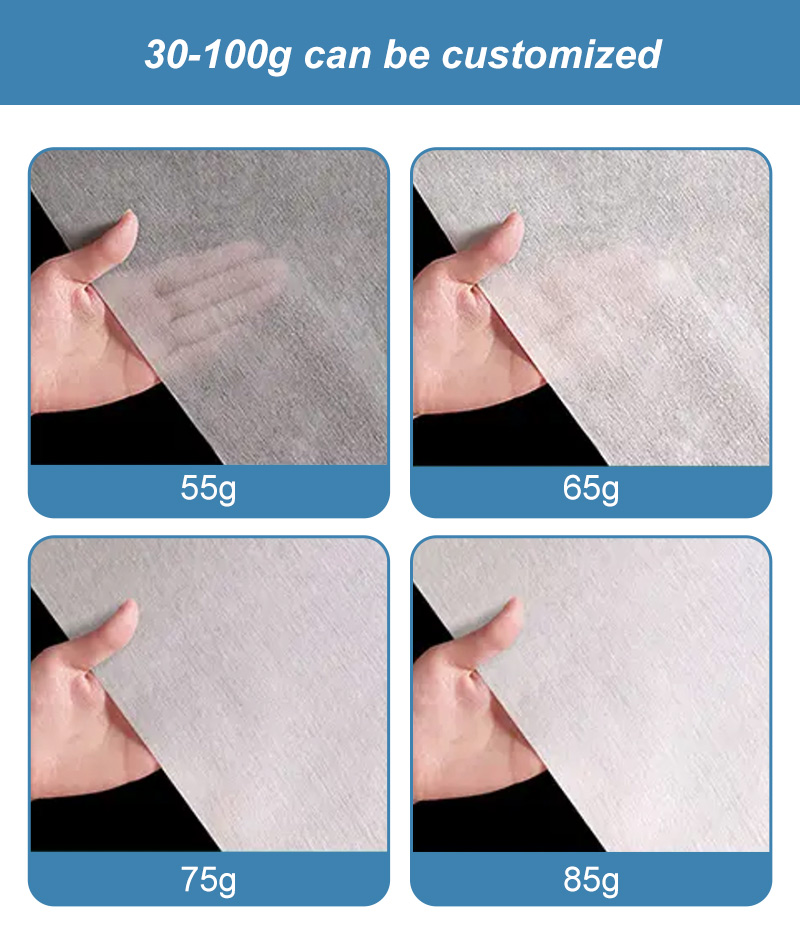

| Weight | 60g/m2-85g/m2 |

| Thickness | 0.18-0.4mm |

| Material | Natural wood pulp + tencel or staple fiber adhesive |

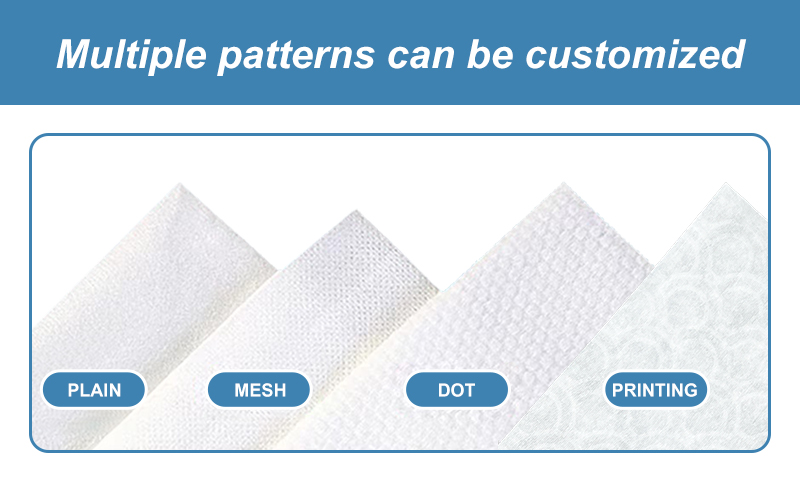

| Pattern | Plain, Embossed ,Printing etc based on customization |

| Width (interval) | 1000mm-2200mm |

| Color | White or customized |

It can be sold in any way such as raw material or point-break coil

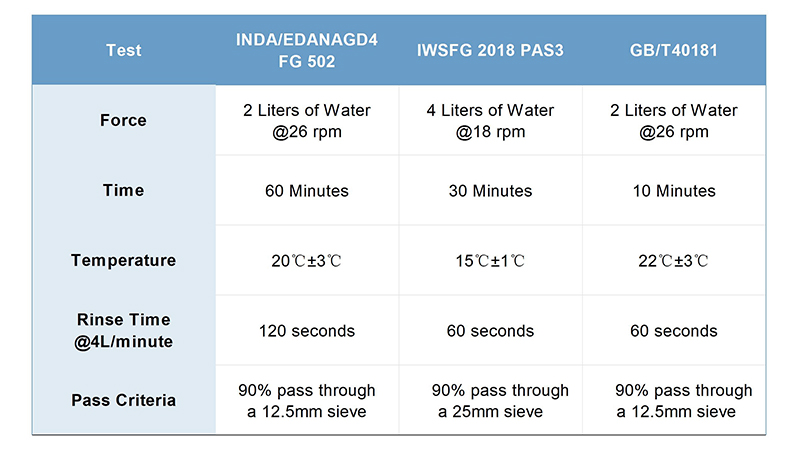

The standards for flushable non-woven fabrics:

1.Flushability: Nonwoven fabrics can be quickly decomposed and dissolved in water under certain conditions. The flushability is usually evaluated by soaking it in water for a certain period of time and observing whether it can be decomposed and dissolved.

2.Decomposition time: The decomposition time of flushable non-woven fabrics should comply with the standards of relevant countries or regions. Generally speaking, the shorter the decomposition time, the less impact on the environment.

3. Decomposition products: The decomposed non-woven fabric should not produce any harmful substances, ensuring no harm to the environment and human body.

4. Physical properties: The physical properties of flushable non-woven fabrics should be similar to those of ordinary non-woven fabrics, including tensile strength, elongation at break, etc., to ensure their reliability during use.

5.Packaging label: The packaging of flushable non-woven fabrics should be clearly marked with "flushable" and related symbols so that users can use and handle them correctly.

It should be noted that the standards for flushable nonwovens may vary from country to country, so when using and selecting them, local standards and regulations should be followed. These standards are formulated to ensure that flushable nonwovens can effectively reduce the generation of solid waste and promote environmental protection after use.

We are proud to offer OEM/ODM support and uphold strict quality control standards with ISO, GMP, BSCI, and SGS certifications. Our products are available for both retailers and wholesalers, and we provide comprehensive one-stop service!

Why Choose us?

1. We have passed many qualification certifications: ISO 9001:2015, ISO 13485:2016, FSC, CE, SGS, FDA, CMA&CNAS, ANVISA, NQA, etc.

2. From 2017 to 2022, Yunge medical products have been exported to 100+ countries and regions in America, Europe, Asia, Africa and Oceania, and are providing practical products and quality services to 5,000+customers around the world.

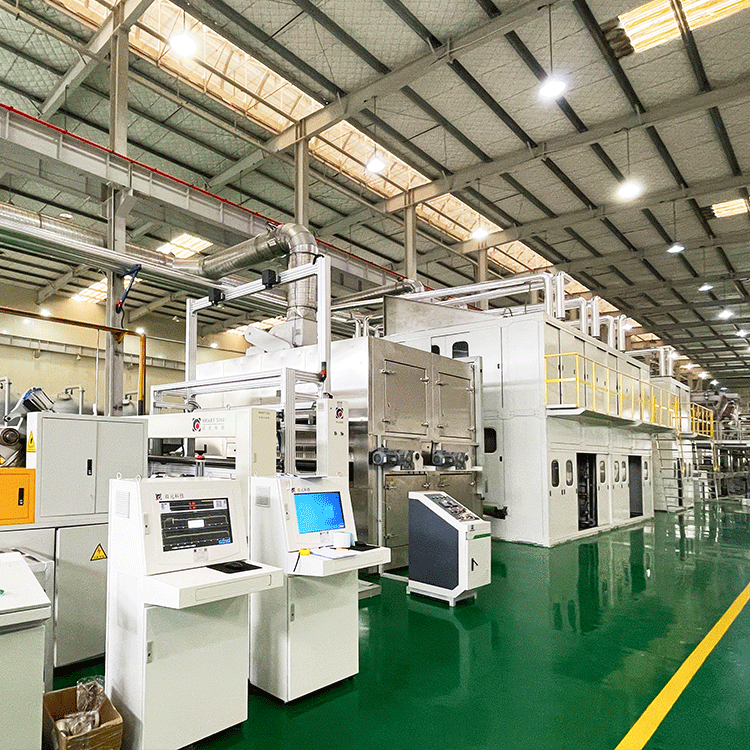

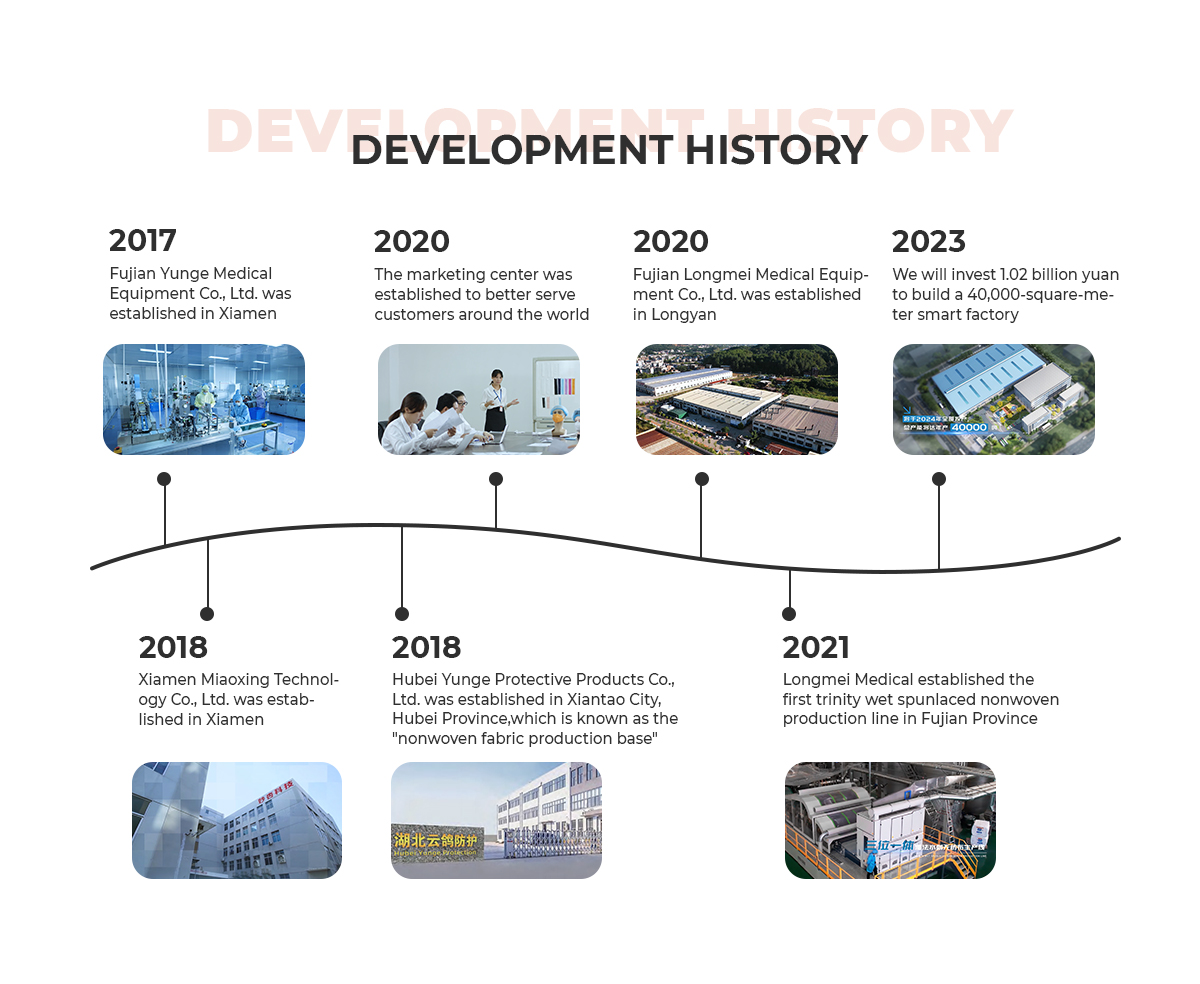

3. Since 2017, in order to provide better products and services to customers around the world, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

4.150,000 square meters workshop can produce 40,000 tons of spunlaced nonwovens and 1 billion+of medical protection products every year;

5.20000 square meters logistics transit center, automatic management system, so that every link of logistics is orderly.

6. Professional quality inspection laboratory can carry out 21 inspection items of spunlaced nonwovens and various professional quality inspection items of a full range of medical protective articles.

7. 100,000-level cleanliness purification workshop

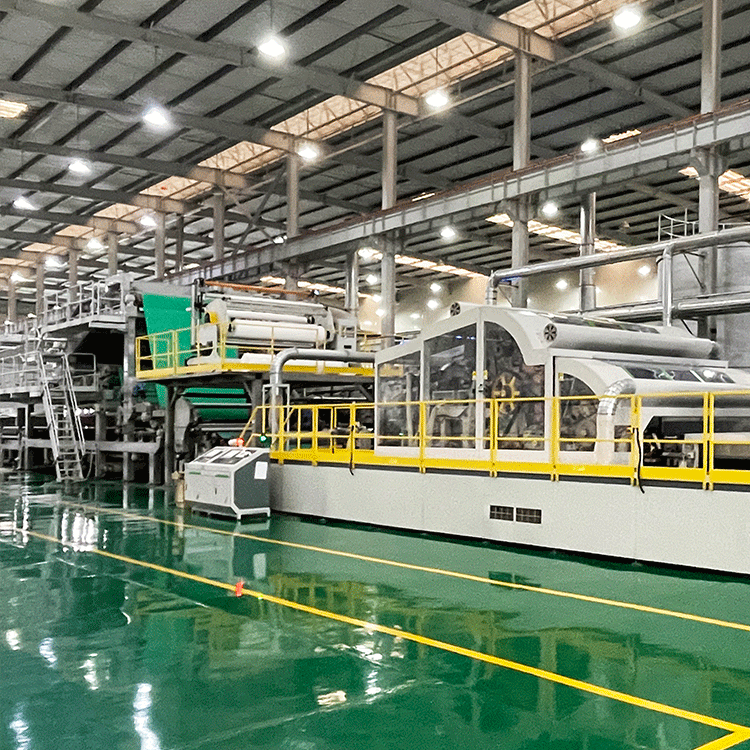

8. Spunlaced nonwovens are recycled in production to realize zero sewage discharge, and the whole process of "one-stop" and "one-button" automatic production is adopted. The whole process of the production line from feeding and cleaning to carding, spunlace, drying and winding is fully automatic.

In order to provide better products and services to customers around the world, since 2017, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

Leave Your Message:

-

Diamond Pattern Spunlace Non Woven Fabric Wipes

-

Spunlace non woven fabric for beauty care used

-

spunlace nonwoven fabric jumbo roll for industr...

-

Blue Non Woven Fabric Rolls Industrial Wipes

-

Multi-Colored Woodpulp Polyester Non Woven Fabr...

-

Different Pattern Non Woven Fabric Rolls

-

Oil Stain Cleaning Industrial Non Woven Fabric ...