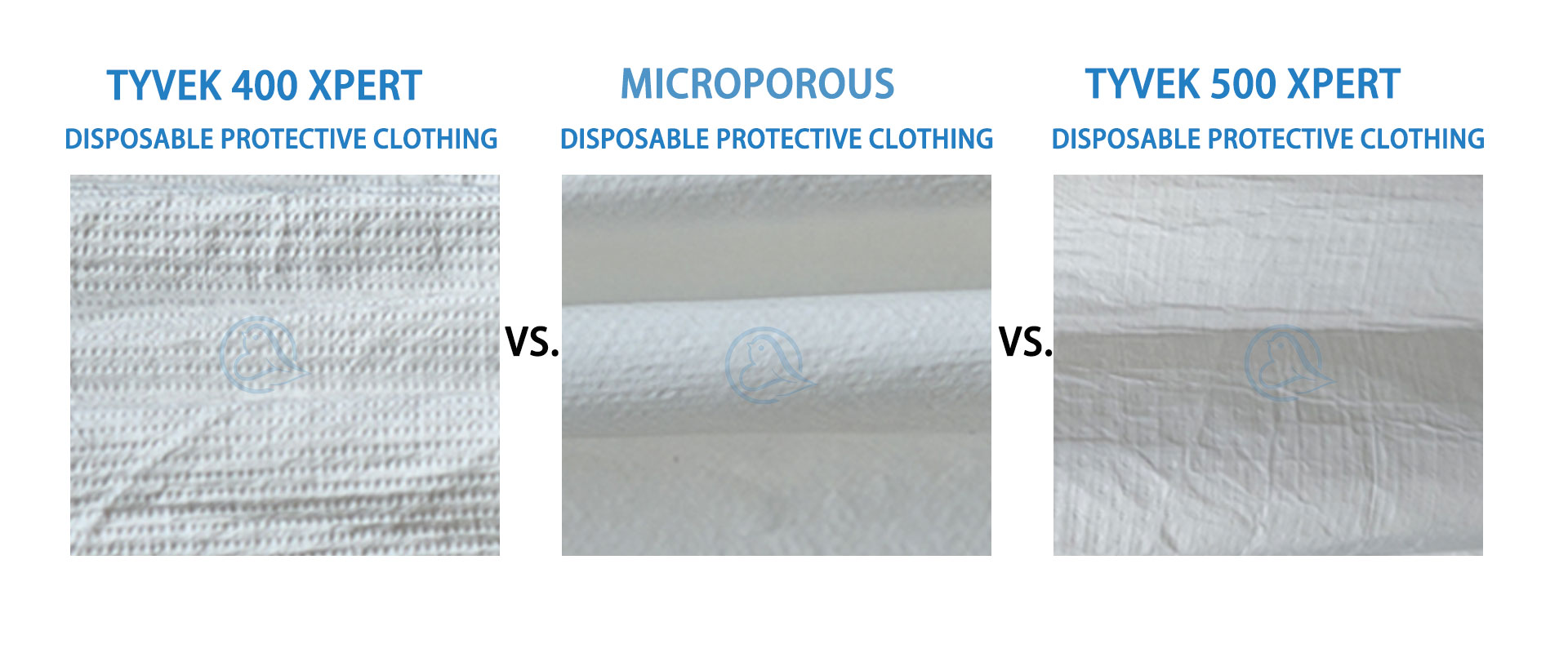

When it comes to protective coveralls, selecting the right type is essential to ensure safety, comfort, and efficiency in various work environments. Whether you need protection against dust, chemicals, or liquid splashes, choosing between DuPont Tyvek 400, DuPont Tyvek 500, and Microporous Disposable Coveralls can make a significant difference. This guide compares their key features to help you make the best choice.

Tyvek 400 Disposable Coveralls

Material & Features:

Made from high-density polyethylene (Tyvek®) with a non-porous, spunbonded structure.

Effective dust protection: Blocks fine particles such as dust, asbestos, and paint particles.

Mild liquid resistance: Can withstand light liquid splashes but not suitable for chemical-heavy environments.

Good breathability: Lightweight and comfortable for long hours of wear.

Best For:

Industrial work, construction, and cleaning environments.

Painting, asbestos removal, and general dust protection

Tyvek 500 Disposable Coveralls

Material & Features:

Also made from high-density polyethylene (Tyvek®) but with added coatings for improved protection.

Enhanced liquid resistance: Offers better protection against low-concentration chemical splashes compared to Tyvek 400.

Higher particle protection: Ideal for demanding industrial settings.

Moderate breathability: Slightly heavier than Tyvek 400 but still comfortable.

Best For:

Laboratories, chemical handling, and pharmaceutical industries.

Higher-risk environments requiring extra protection.

Microporous Disposable Coveralls

Material & Features:

Constructed from microporous film + polypropylene non-woven fabric.

Superior liquid protection: Shields against blood, bodily fluids, and mild chemical splashes.

Best breathability: Microporous material allows moisture vapor to escape, reducing heat buildup.

Moderate durability: Less durable than Tyvek 500 but offers good protection with enhanced comfort.

Best For:

Medical and laboratory use, food processing, and pharmaceutical industries.

Work environments requiring a balance of liquid resistance and breathability.

Comparison Table: Tyvek 400 vs. Tyvek 500 vs. Microporous Coveralls

| Feature | Tyvek 400 Coverall | Tyvek 500 Coverall | Microporous Coverall |

|---|---|---|---|

| Material | High-density polyethylene (Tyvek®) | High-density polyethylene (Tyvek®) | Microporous film + polypropylene non-woven fabric |

| Breathability | Good, suitable for prolonged wear | Moderate, slightly less breathable | Best breathability, most comfortable to wear |

| Particle Protection | Strong | Stronger | Strong |

| Liquid Resistance | Light protection | Medium protection | Good protection |

| Chemical Resistance | Low | High, suitable for mild chemicals | Moderate, suitable for medical use |

| Best Use Cases | General industry, dust protection | Chemical handling, pharmaceutical labs | Medical, pharmaceutical, food processing |

How to Choose the Right Disposable Coverall?

For general dust protection and light splashes, go with Tyvek 400.

For environments requiring stronger protection against chemicals and liquid splashes, choose Tyvek 500.

For medical, pharmaceutical, or food industry applications where breathability is essential, opt for Microporous Coveralls.

Final Thoughts

Selecting the right coverall depends on your specific workplace needs. DuPont Tyvek 400 and 500 offer robust protection for industrial and chemical-related tasks, while microporous coveralls provide an excellent balance between breathability and liquid resistance for medical and food-related environments. Investing in the correct disposable coverall ensures maximum safety and comfort while maintaining productivity in hazardous or controlled conditions.

For bulk orders and inquiries, contact us today!

Post time: Mar-21-2025