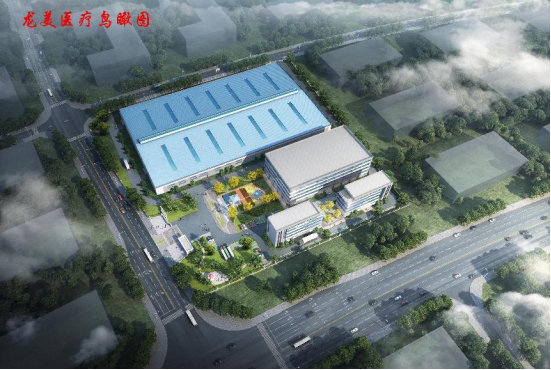

Founded in November 2020, it is located in Longyan High-tech Development Zone.

The project is divided into two phases. In the first phase, a 7,000-square-meter workshop has been put into production with an annual production capacity of 8,000 tons. The second phase of the project, with an investment of 1.02 billion yuan, will build a 40,000-square-meter smart factory, which will be fully put into operation in 2024, with a total production capacity of 40,000 tons/year.

Trinity Wet Spunlaced Nonwoven Production Line

At present, there is the only trinity wet spunlaced nonwoven production line in Fujian and Guangdong provinces, which is recycled in production, achieving zero sewage discharge, supporting high-speed, high-yield and high-quality carding machines and compound round cage dust removal units, and adopting "one-stop" and "one-click" full-process automatic production, and the whole process of the production line is fully automated from feeding and cleaning to carding, spunlacing, drying and winding.

Our products cover PP wood pulp composite spunlaced nonwovens, polyester wood pulp composite spunlaced nonwovens, viscose wood pulp spunlaced nonwovens, degradable and washable spunlaced nonwovens and so on. It is widely used in the fields of cleaning and wiping, medical protection, sanitary materials for wet wipes, beauty care, packaging materials, etc. in the electronic industry, such as dust-free cloth, dust-free paper, medical protective clothing, medical masks, wet wipes, wet toilet paper, facial masks, non-woven packaging bags, etc.

Spunlaced Nonwovens

Strict selection of materials, laying a quality foundation from the source. A stable and reliable large-scale direct supplier of raw materials uses high-quality polyester, wood pulp imported from Canada and high-priced viscose and other raw materials according to the requirements of different products. Every production link, set strict standards, and check the quality at every step.

In order to improve the ability of sustainable operation, we take "innovation-driven" as a long-term development strategy, establish and improve the physical and biochemical experiment center, and set up the enterprise technology research center.

It has a professional quality inspection laboratory, which can carry out 21 authoritative tests covering almost all the test items of spunlaced materials, ensuring that each product has undergone layer-by-layer polishing of details and performance.

Post time: Mar-15-2023