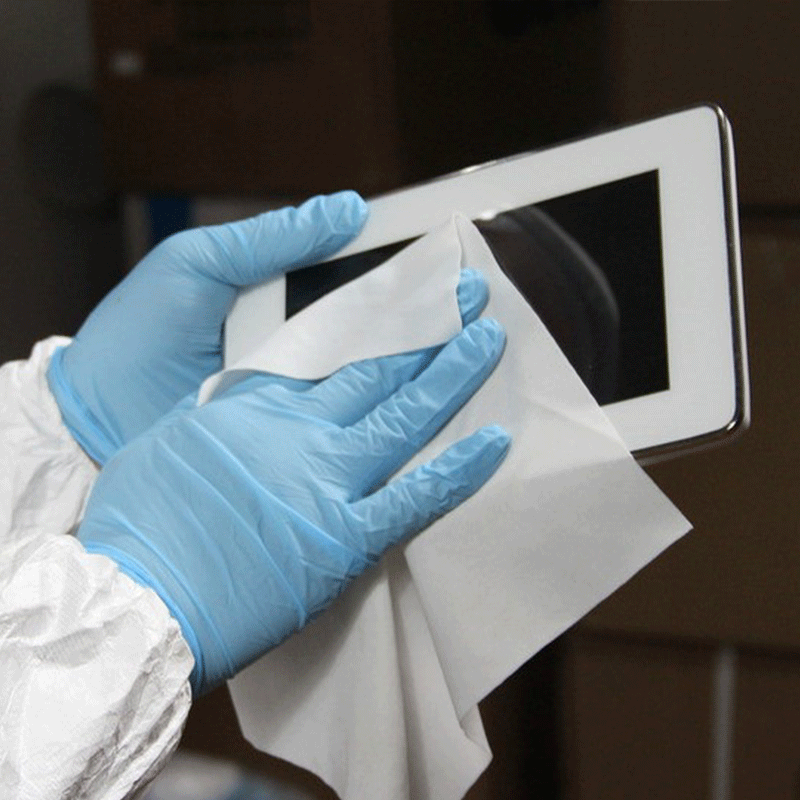

In highly controlled environments such as cleanrooms, pharmaceutical labs, and electronic manufacturing facilities, maintaining a contamination-free workspace is critical. Traditional wipes, often made from woven materials like cotton or polyester, may not meet the rigorous standards required in these sensitive environments. Nonwoven cleanroom wipes have gained popularity due to their superior performance across various applications. Let’s explore their advantages from the perspectives of application scenarios, material composition, and key benefits.

Comparison of Nonwoven vs. Traditional Cleanroom Wipers

1.Application Scenarios

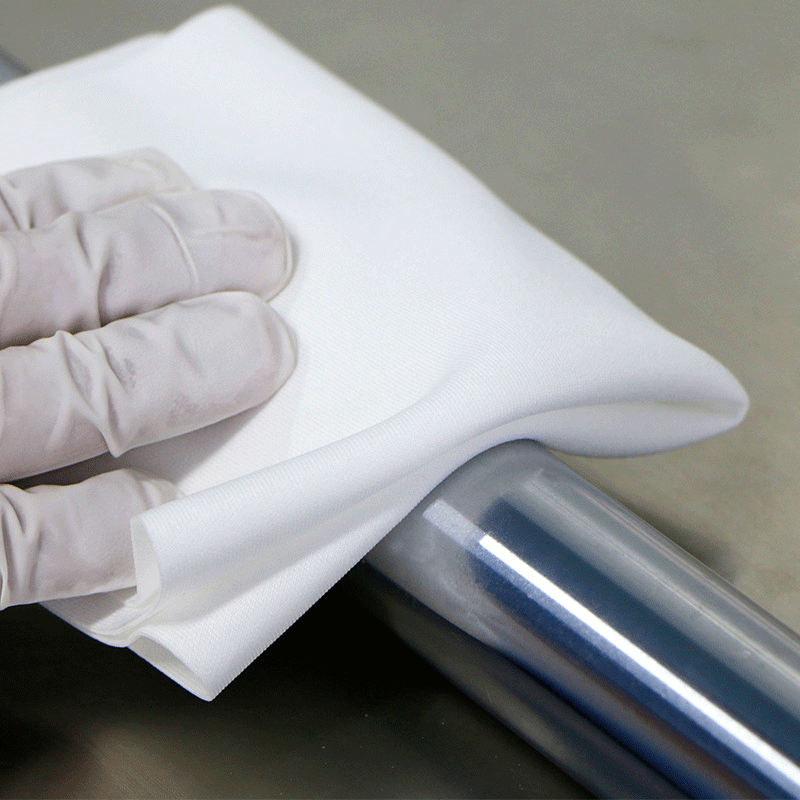

(1)Semiconductor and Electronics Manufacturing

In semiconductor fabrication, even the smallest particle contamination can lead to defective microchips. Traditional wipes tend to shed fibers, which can compromise the precision of circuit boards and wafers. Nonwoven cleanroom wipes, made from materials like polyester-cellulose blends or polypropylene, minimize lint and particulate generation. Their ultra-low particle shedding ensures that delicate electronic components remain free from contaminants, maintaining product quality and reducing failure rates.

(2)Pharmaceutical and Biotechnology Labs

Sterility is a top priority in pharmaceutical and biotechnology cleanrooms, where any contamination can compromise drug efficacy or pose serious health risks. Traditional woven wipes are not designed to withstand exposure to harsh sterilizing agents like isopropyl alcohol (IPA) or hydrogen peroxide. In contrast, nonwoven cleanroom wipes are engineered for chemical compatibility, ensuring they can be used with disinfectants without degrading. Their high absorbency also makes them effective for spill control and surface disinfection.

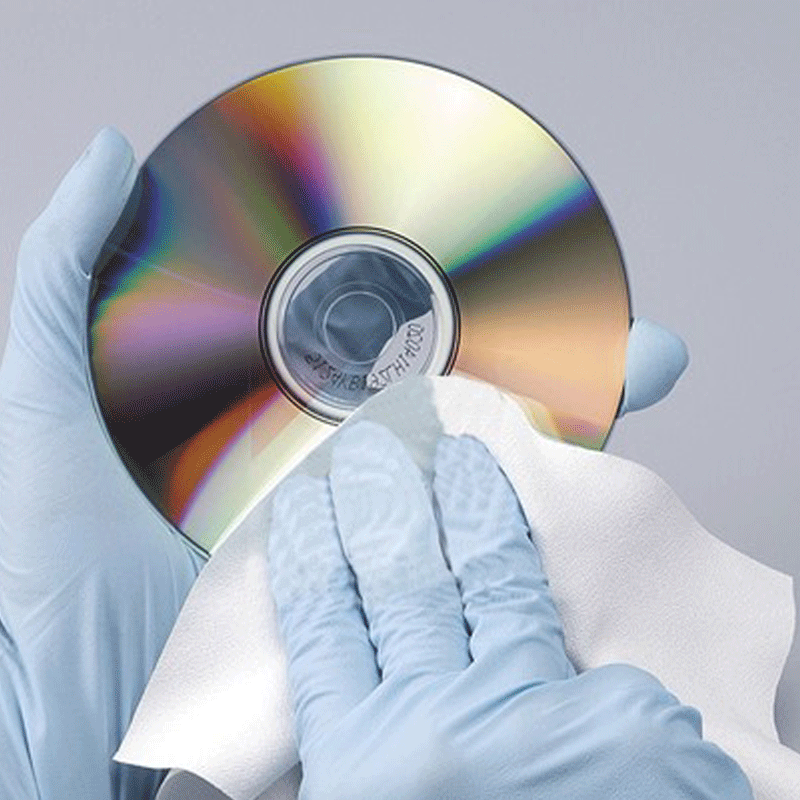

(3)Medical Device Manufacturing

The production of medical devices such as implants, syringes, and surgical tools requires a pristine environment to meet strict regulatory standards. Traditional wipes may introduce contaminants due to their fibrous nature. Nonwoven wipes, however, are designed to be sterile and highly absorbent, allowing manufacturers to clean surfaces and equipment efficiently while maintaining compliance with FDA and ISO standards.

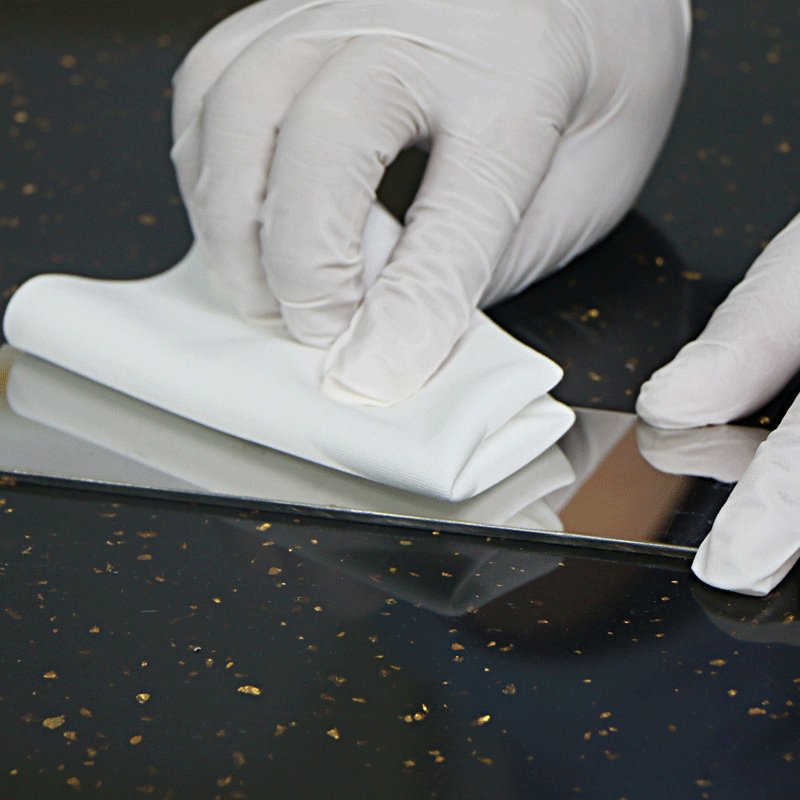

(4)Aerospace and Optics Industries

In aerospace and optical component manufacturing, surface contamination can affect the performance of critical instruments. Traditional wipes often leave behind residues that can distort optical lenses or damage sensitive coatings. Nonwoven cleanroom wipes offer a lint-free cleaning solution, ensuring that high-precision components such as satellite lenses and aerospace instruments remain flawless and function as intended.

(5)Food Processing and Packaging

Food safety regulations require stringent hygiene standards to prevent microbial contamination. Traditional woven wipes can trap bacteria and moisture, leading to potential food safety hazards. Nonwoven cleanroom wipes, with their high absorbency and low particle release, are ideal for cleaning surfaces in food processing plants. They help maintain hygiene while reducing the risk of cross-contamination.

(6)Automotive and Industrial Manufacturing

Automotive and industrial sectors rely on contamination control to ensure product reliability, particularly in precision engineering applications. Nonwoven wipes are highly effective in removing grease, oils, and fine metal particles from machinery and workstations. Their durability and chemical resistance make them superior to traditional wipes, which may deteriorate under heavy industrial use.

2. Material Composition

Traditional wipes are generally woven from natural or synthetic fibers such as cotton or polyester. While they may be reusable, their fibrous nature makes them prone to shedding and absorbing moisture inefficiently. In contrast, nonwoven cleanroom wipes are made from synthetic materials like polyester, polypropylene, and cellulose blends. These materials are engineered to provide:

(1)Low particle generation

(2)High chemical resistance

(3)Excellent absorbency

(4)Durable and lint-free performance

3. Key Advantages of Nonwoven Cleanroom Wipers

(1)Superior Contamination Control: Nonwoven wipes minimize fiber shedding, ensuring a cleaner environment in controlled spaces.

(2)Enhanced Absorbency: Their unique structure allows them to absorb liquids and contaminants more efficiently than woven alternatives.

(3)Chemical Compatibility: Unlike traditional wipes, nonwoven cleanroom wipes can withstand harsh sterilization chemicals without degrading.

(4)Cost-Effectiveness: They offer a balance between durability and affordability, making them a cost-efficient solution for businesses.

(5)Customizable Properties: Available in different sizes, textures, and compositions, nonwoven cleanroom wipes can be tailored to specific industry needs.

Conclusion

Across various industries, nonwoven cleanroom wipes outperform traditional wipes in critical applications requiring contamination control, sterility, and chemical resistance. Their low particle generation, superior absorbency, and compatibility with harsh disinfectants make them the preferred choice in cleanrooms and controlled environments. As industries continue to demand higher cleanliness standards, nonwoven cleanroom wipes will remain an essential tool for maintaining quality, compliance, and operational efficiency.

Post time: Mar-14-2025