Description:

Polyester non-woven fabric is a non-woven material made of polyester fiber. Polyester is a synthetic fiber with excellent wear resistance, fading resistance and easy cleaning, so the non-woven fabric made from it is very durable and easy to care for. Polyester non-woven fabrics are usually used to make household items, clothing, packaging materials, filter materials, etc. Because of their waterproof, breathable, antibacterial and other properties, they are widely used in various fields.

The production process of polyester non-woven fabrics usually includes fiber opening, pre-cutting, pre-joining, pre-stitching, shaping, forming and other processes. Through hot rolling, hot air or chemical treatment, the fibers are combined with each other to form a uniform network structure, thereby forming a non-woven material.

Specification:

| Weight | 30g/m2-125g/m2 |

| Thickness | 0.18-0.45mm |

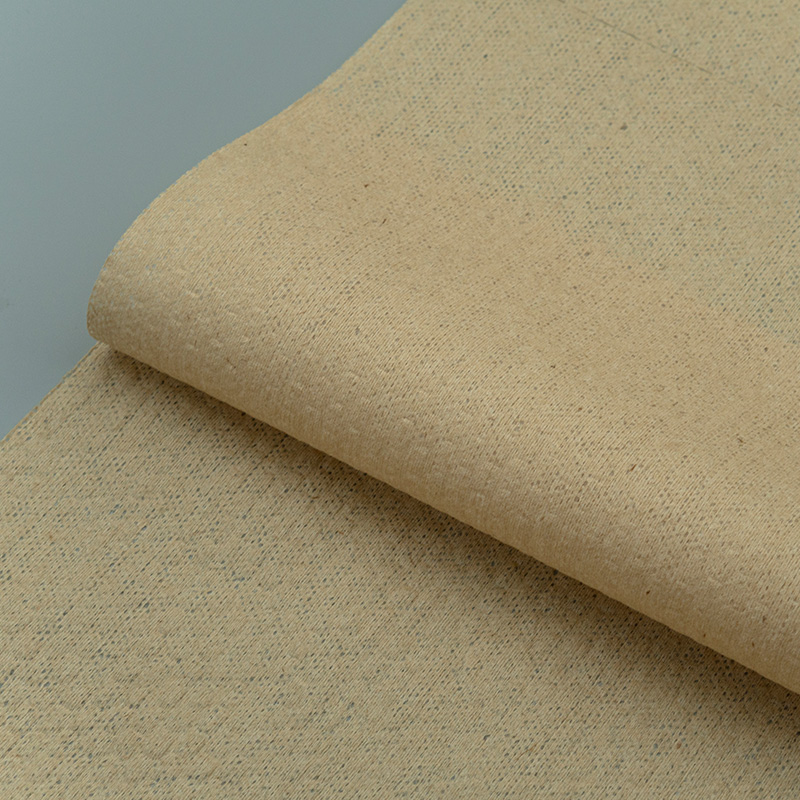

| Material | 100% Viscose/Rayon |

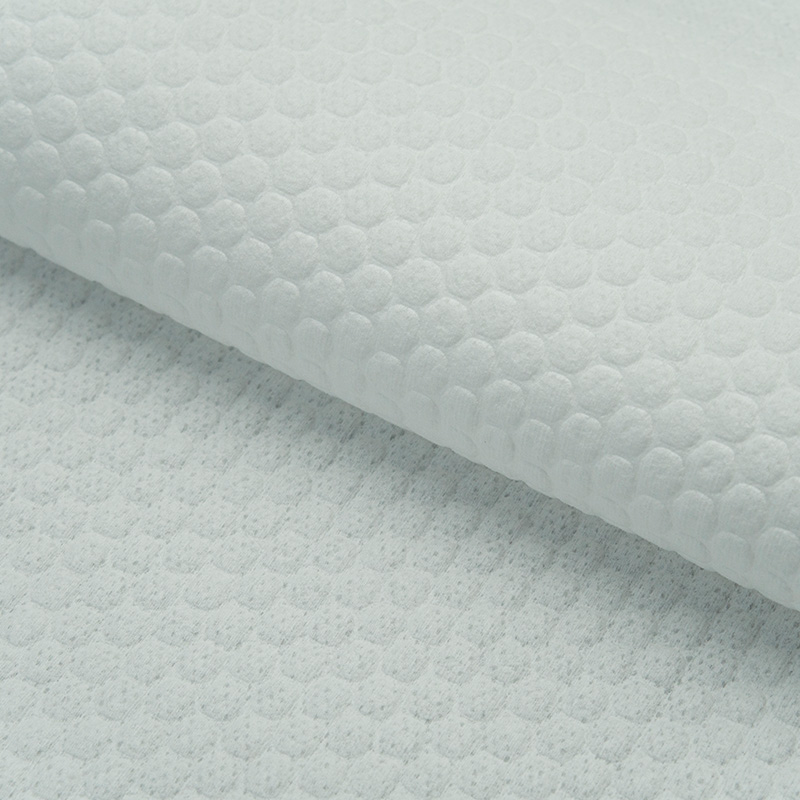

| Pattern | Plain, Embossed etc based on customization |

| Width (interval) | 110mm-230mm |

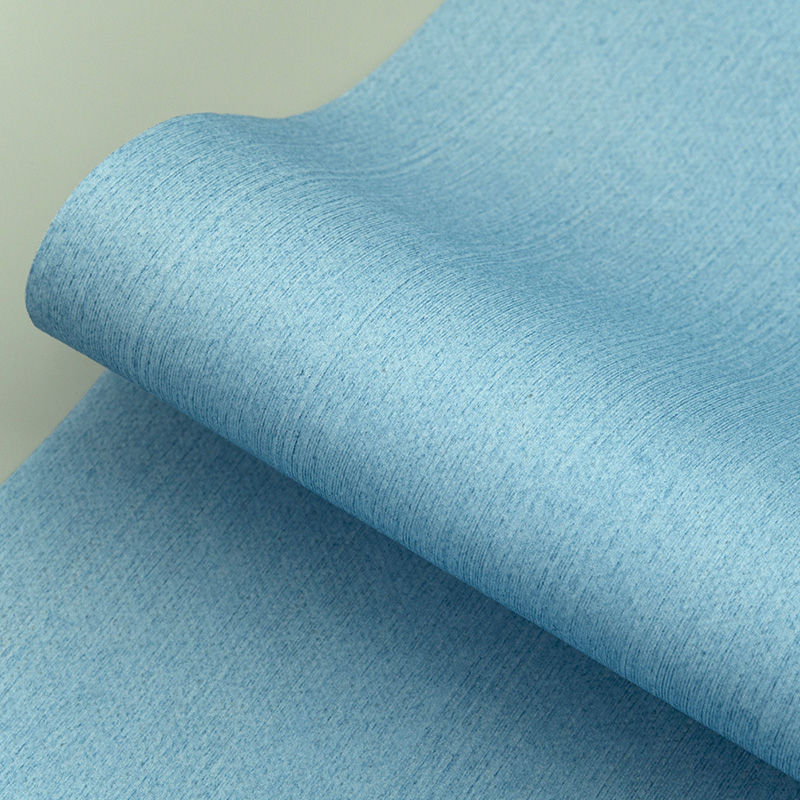

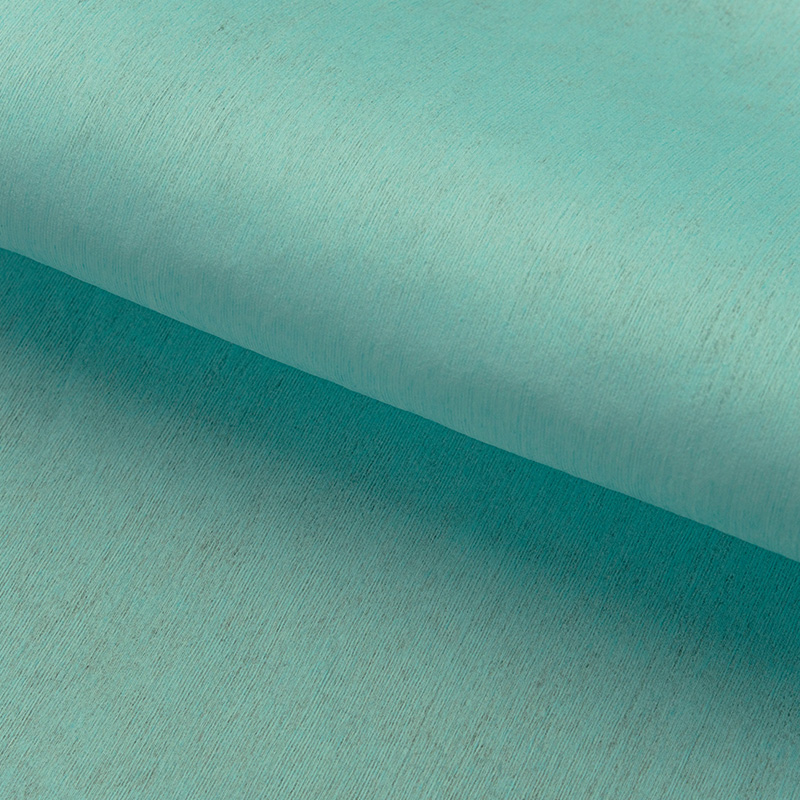

| Color | Blue, green, red etc based on customization |

It can be sold in any way such as raw material or point-break coil

Usages:

Biodegradable full viscose non-woven fabric is an environmentally friendly and sustainable material with good degradability and a relatively environmentally friendly production process. Its main uses include:

1.Environmentally friendly and sustainable applications: Due to its degradability, fully viscose non-woven fabric is regarded as an environmentally friendly material that can quickly decompose in the natural environment and reduce environmental pressure.

2.Agricultural planting covering materials: Non-woven fabrics can be used as moisturizing and heat-insulating agricultural planting covering materials to help maintain soil moisture and temperature, promote plant growth, and improve crop yield and quality.

3.Customized processing of personal care products: Biodegradable fully viscose non-woven fabrics can be used to customize personal care products such as wet wipes and cotton wipes, demonstrating its wide application in the field of personal care.

Our Company takes advantage of its geographical and resource advantages to provide customized OEM services for degradable spunlace non-woven fabrics, as well as wet wipes, cotton towels and other non-woven products, providing customers with high-quality environmentally friendly products.

Other Material of Spunlace Nonwoven Fabric For Your Choose:

More Details Please massage us!

We are proud to offer OEM/ODM support and uphold strict quality control standards with ISO, GMP, BSCI, and SGS certifications. Our products are available for both retailers and wholesalers, and we provide comprehensive one-stop service!

Why Choose us?

1. We have passed many qualification certifications: ISO 9001:2015, ISO 13485:2016, FSC, CE, SGS, FDA, CMA&CNAS, ANVISA, NQA, etc.

2. From 2017 to 2022, Yunge medical products have been exported to 100+ countries and regions in America, Europe, Asia, Africa and Oceania, and are providing practical products and quality services to 5,000+customers around the world.

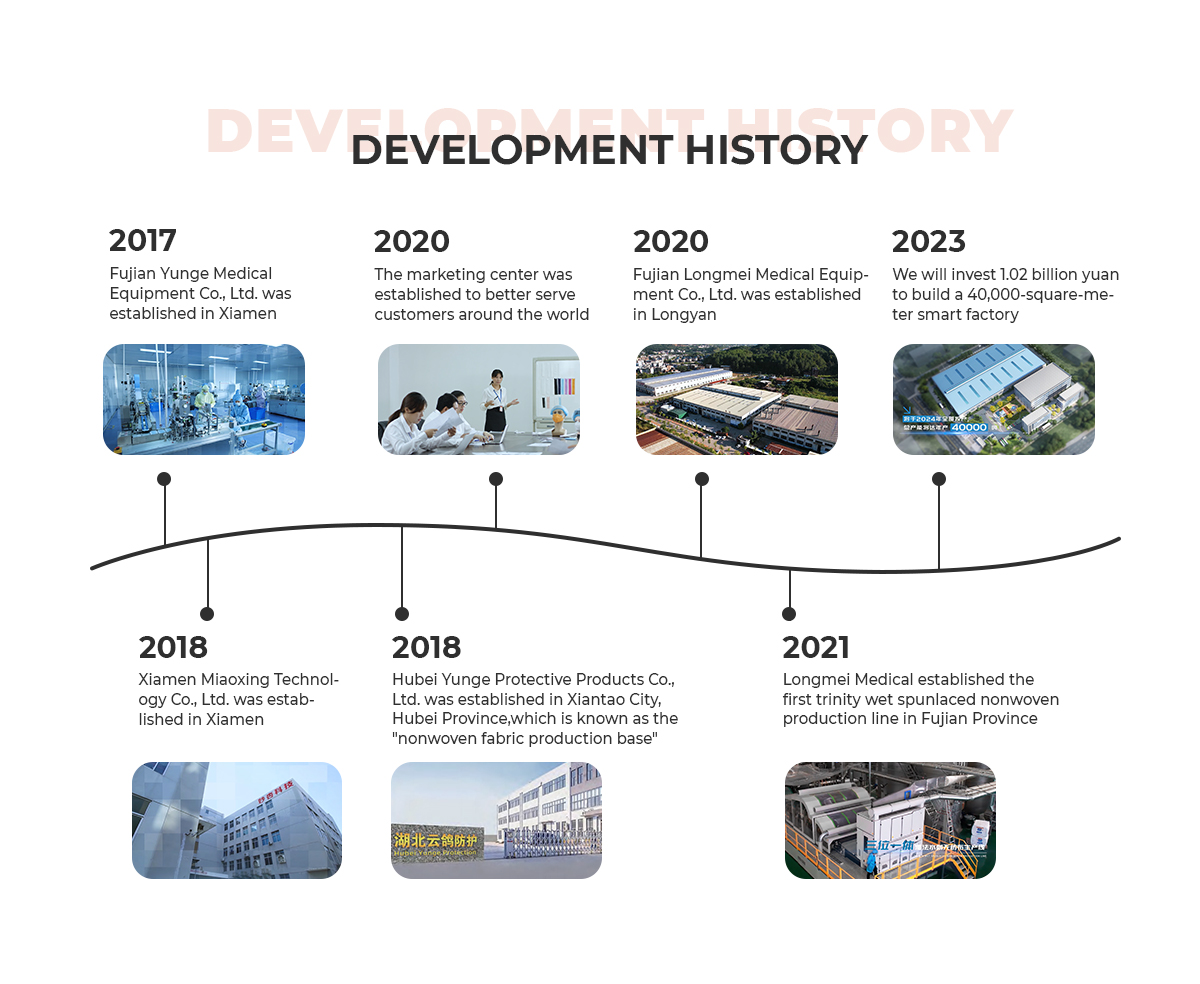

3. Since 2017, in order to provide better products and services to customers around the world, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

4.150,000 square meters workshop can produce 40,000 tons of spunlaced nonwovens and 1 billion+of medical protection products every year;

5.20000 square meters logistics transit center, automatic management system, so that every link of logistics is orderly.

6. Professional quality inspection laboratory can carry out 21 inspection items of spunlaced nonwovens and various professional quality inspection items of a full range of medical protective articles.

7. 100,000-level cleanliness purification workshop

8. Spunlaced nonwovens are recycled in production to realize zero sewage discharge, and the whole process of "one-stop" and "one-button" automatic production is adopted. The whole process of the production line from feeding and cleaning to carding, spunlace, drying and winding is fully automatic.

In order to provide better products and services to customers around the world, since 2017, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

Leave Your Message:

-

Diamond Pattern Spunlace Non Woven Fabric Wipes

-

Spunlace non woven fabric for beauty care used

-

spunlace nonwoven fabric jumbo roll for industr...

-

Blue Non Woven Fabric Rolls Industrial Wipes

-

Multi-Colored Woodpulp Polyester Non Woven Fabr...

-

Different Pattern Non Woven Fabric Rolls

-

Oil Stain Cleaning Industrial Non Woven Fabric ...

-

100% Viscose/Rayon Degradable Non Woven Fabric ...

-

Biodegradable and Flushable Non Woven Fabric Ro...

-

Viscose+Polyester Degradable Spunlace Non Woven...

-

Blue non woven fabric rolls for industrial wiping

-

Black Single Elastic Non Woven Disposable Clip ...

-

35gsm PP Non Woven Fabric White Disposable Prot...

-

4ply Non Woven Faric Disposable KF94 Facemask W...

-

99% Pure Water Non Woven Fabric Baby Wet Wipes