Description:

Specifications:

| Material | PP, SMS,PP+PE non woven ventilation film, can be customized |

| Weight | Non-woven Fabric (30-60gsm);Breathable Film (48-75gsm) |

| Color | White/Blue /Yellow or customized |

| Type | With Strip, Without Strip |

| Size | S/M/XL/XXL/XXXL, Support Customized |

| Certifications | CE, ISO 9001, ISO 13485 and others |

| Performance Levels | Type 4, 5, 6 |

| Shelf Life | 3 Years |

| Package | 1 PC/Polybag, 50 PCS/Carton |

Application:

Medical, Industrial, Chemical, Agricultural, Cleaning and Disinfection, Painting, Personal protective, Labs, Patient Care, and refineries etc

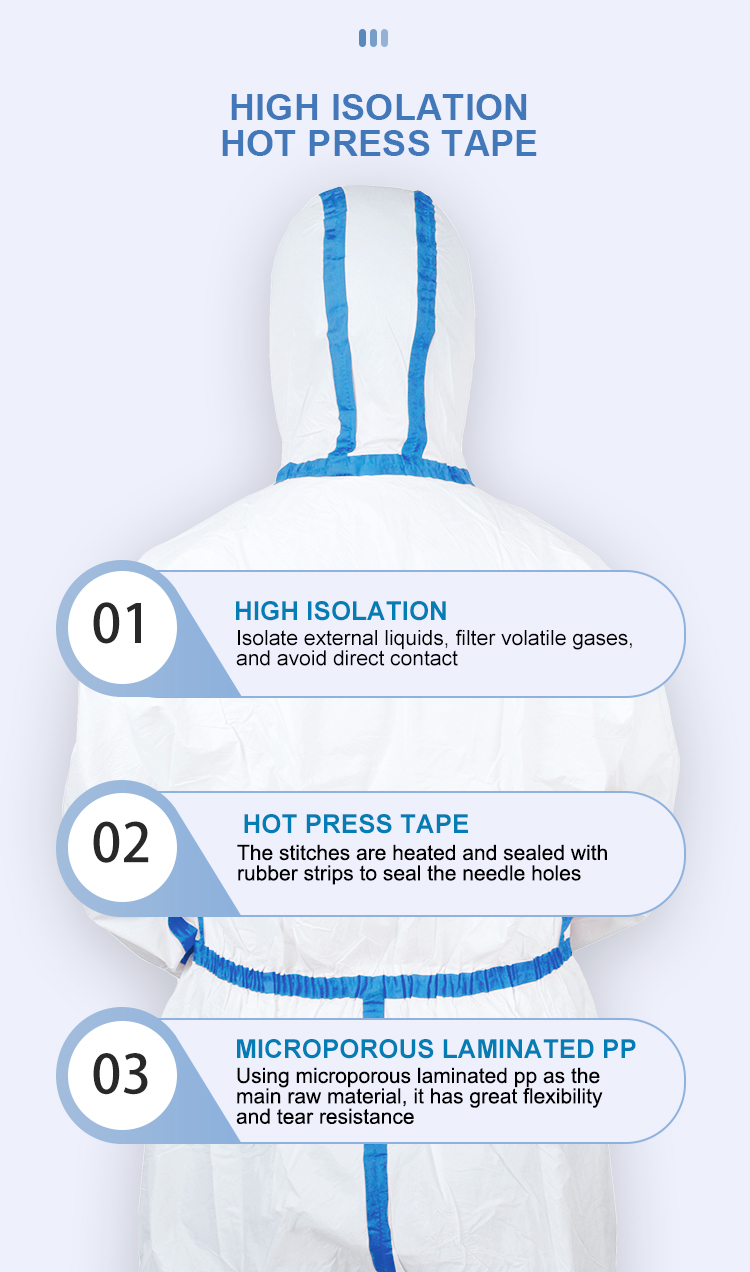

Details:

Features:

4. Zipper with a self-adhesive storm flap for added defense against contaminants

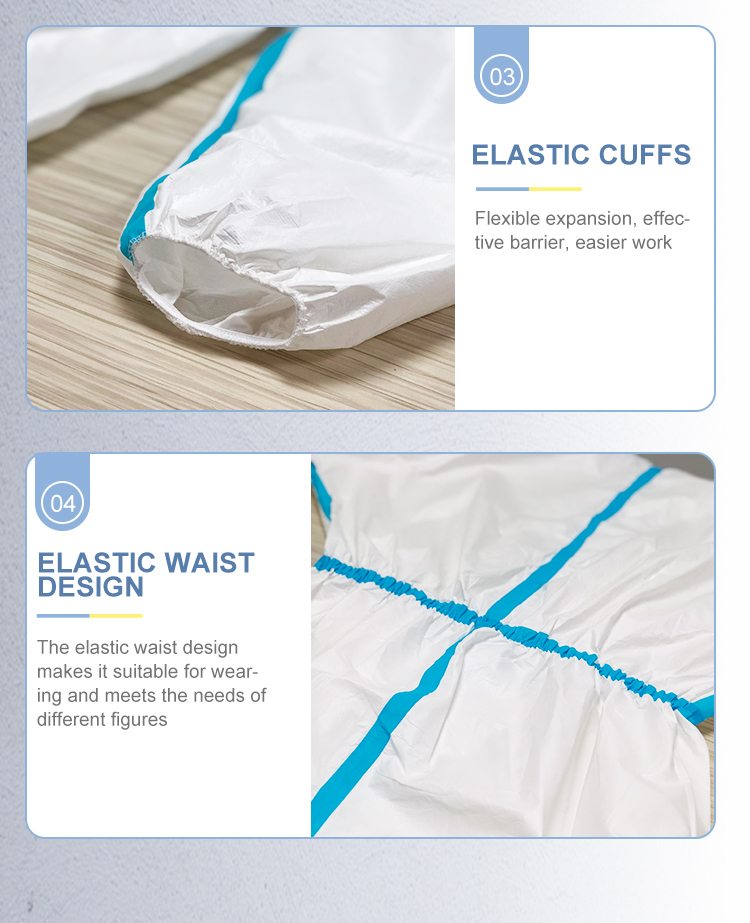

5.Elastic waist, cuff, and ankle design ensures a secure fit and protection

6.Seamless shoulders and sleeve tops for enhanced strength and protection

Benefits:

At Yunge Medical, we are committed to manufacturing products that stand out nationally and globally and also bring great satisfaction. Our medical jumpsuits are:

2.Comfortable to wear and soft to touch.

3.CE-certified and compliant with national and ISO 13485:2016 quality management standards.

4.Lightweight and breathable.

5.Made with strong anti-static materials to prevent items from clinging to the disposable medical coveralls.

6.Designed to isolate germs and protect the wearer from harmful ultra-fine dust, acid, alkaline, and other liquid.

7.Highly resistant to tear and flame.

8.Available in multiple sizes.

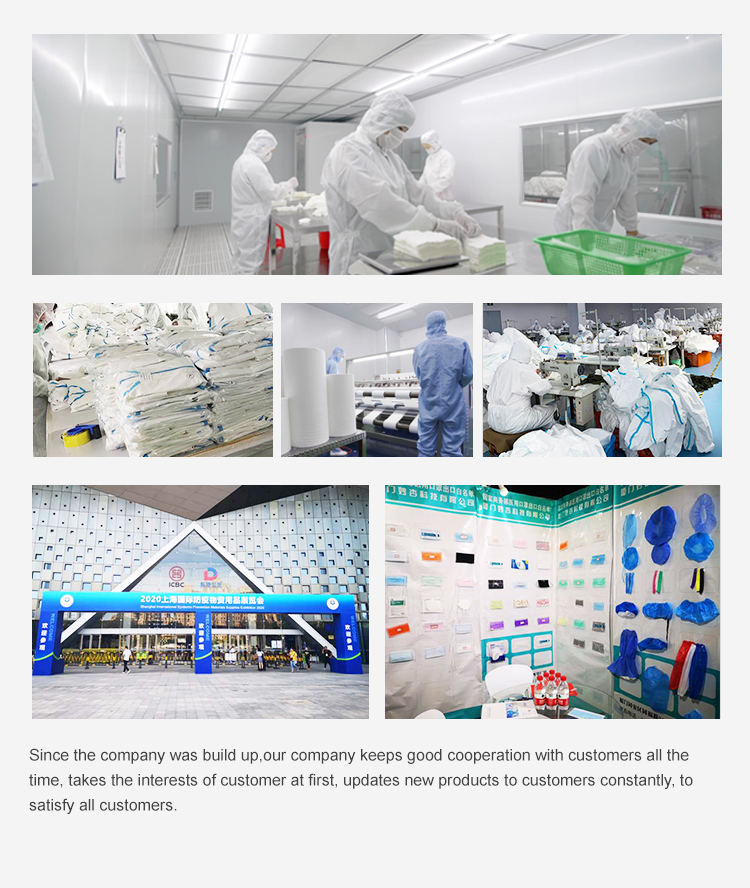

How Yunge Factory Produces Medical Jumpsuits?

Yunge Medical, a reputable medical coverall supplier, is dedicated to upholding core values such as sensitivity, innovation, and efficiency in the production and distribution of high-quality medical disposable coveralls, all while maintaining environmentally sustainable manufacturing processes.

Our production procedures are designed to be eco-friendly, minimizing our carbon footprint while upholding stringent quality standards.

1.Raw Material Selection

We prioritize eco-friendly processes by utilizing disposable rubber for production and selecting suitable latex and nitrile materials to create comfortable, flexible, and easy-to-wear finished products.

2.OEM/ODM Product Development

As a versatile medical protective coverall manufacturer, Yunge is involved in comprehensive research and development, product design, and testing of medical jumpsuits, all within our medical coverall factory.

3.High-Grade Automatic Production Lines

We employ pre-leach, vulcanizing, and post-leach processes to ensure the removal of non-rubber particles and harmful residues, strengthening the material and enhancing durability.

3.Quality Management/Testing

Our commitment to producing high-quality products is reflected in our rigorous quality management and testing procedures. Each disposable medical coverall undergoes comprehensive testing and inspection to ensure high levels of protection, reliability, and compliance with global and national standards.

4.E.T.O Sterilization

We utilize state-of-the-art E.T.O sterilization plants, validated by EN 550 Norms, to inspect the products and ensure their suitability for E.O. sterilization. This process extends the shelf life of the disposable medical coveralls and ensures cleanliness.

5.Custom Packaging Yunge offers a range of packaging solutions and can also provide custom packages tailored to the specific requirements of our clients.

Is Yunge the Reliable Supplier of Medical Disposable Coveralls?

Why Choose us?

Yunge Medical: Your Trusted Global Partner for Non Woven Products

1. Stringent Qualifications: Yunge holds numerous certifications including ISO 9001:2015, ISO 13485:2016, FSC, CE, SGS, FDA, CMA&CNAS, ANVISA, and NQA, ensuring top-notch quality.

2. Global Reach: Yunge's medical products have been exported to over 100 countries and regions, serving 5,000+ customers worldwide with practical products and quality services.

3. Extensive Production Bases: Yunge has established four production bases - Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology, and Hubei Yunge Protection - since 2017 to enhance global product and service delivery.

4. Impressive Manufacturing Capacity: With a 150,000 square meter workshop capable of producing 40,000 tons of spunlaced nonwovens and over 1 billion medical protection products annually, Yunge ensures reliable supply.

5. Efficient Logistics: Yunge's 20,000 square meter logistics transit center, equipped with an automatic management system, ensures orderly and efficient logistics operations.

6. Rigorous Quality Control: Yunge's professional quality inspection laboratory conducts 21 inspection items for spunlaced nonwovens and various quality checks for a comprehensive range of medical protective articles.

7. Cleanroom Facilities: Yunge operates a 100,000-level cleanliness purification workshop, ensuring a sterile environment for the production of medical protective articles.