Description:

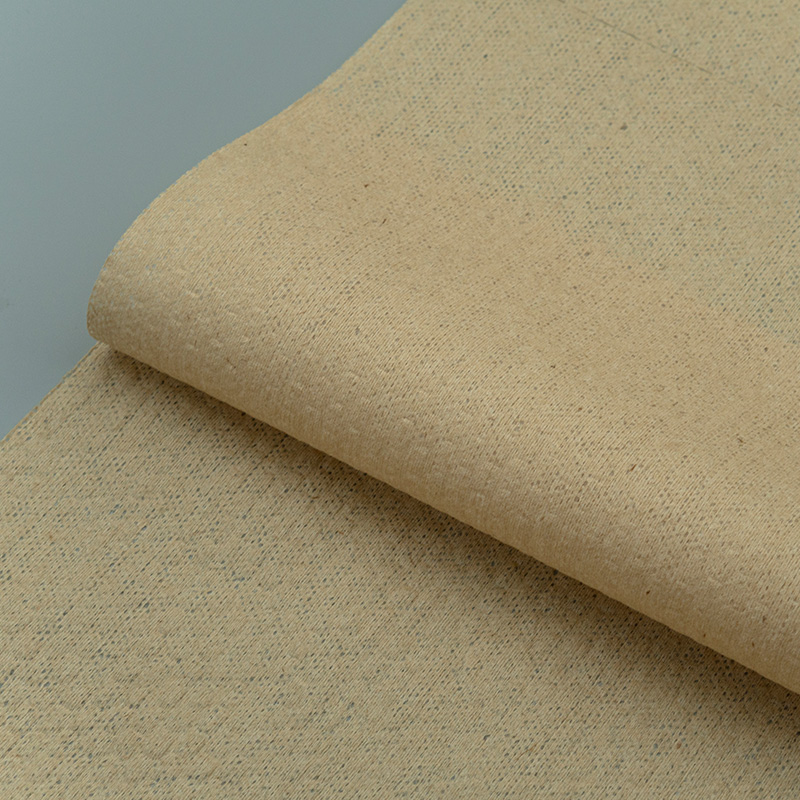

PP wood pulp fabric is made of 70% wood pulp and 30% PP, with a weight of 40-80g and a width of 100-2000mm. The fabric is known for its uniform mesh, strong vertical and horizontal strength, minimal shedding, and softness when wet. It has strong oil removal ability, environmental protection and high cost performance. Common applications include wet wipes (especially in overseas markets), disposable hand towels in hospitals, and home kitchen cleaning.

Specification:

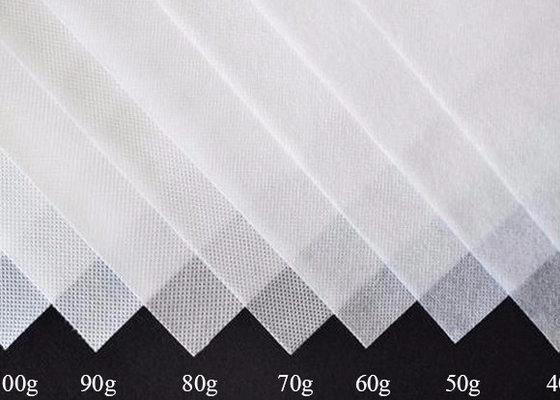

| Weight | 30g/m2-125g/m2 |

| Thickness | 0.18-0.45mm |

| Material | Natural wood pulp +PP |

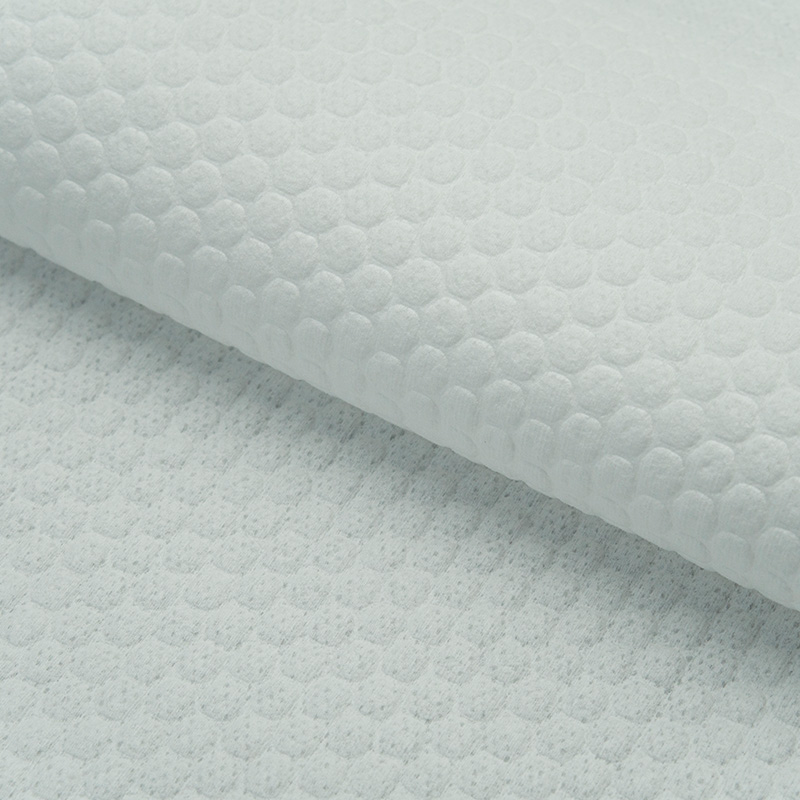

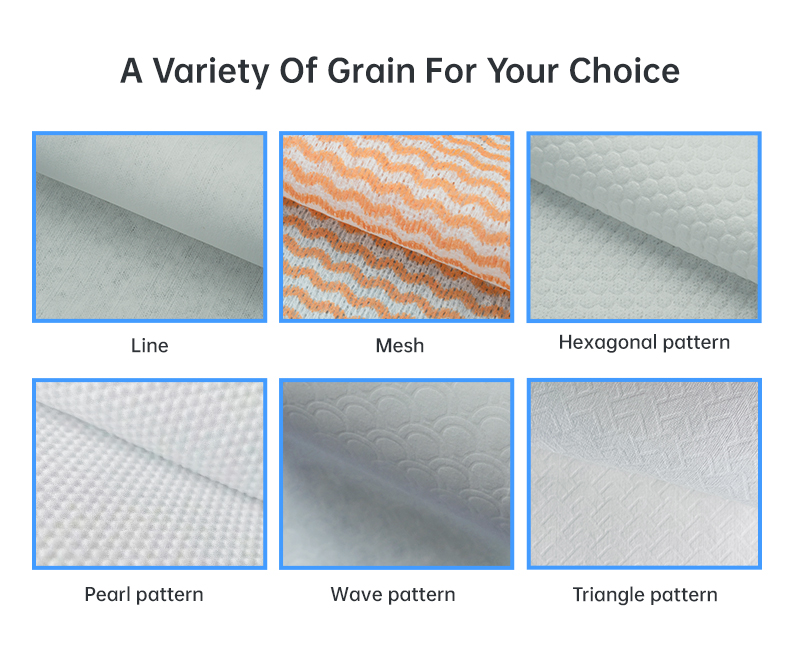

| Pattern | Plain, Embossed ,Printing, mesh etc based on customization |

| Width (interval) | 210mm-230mm |

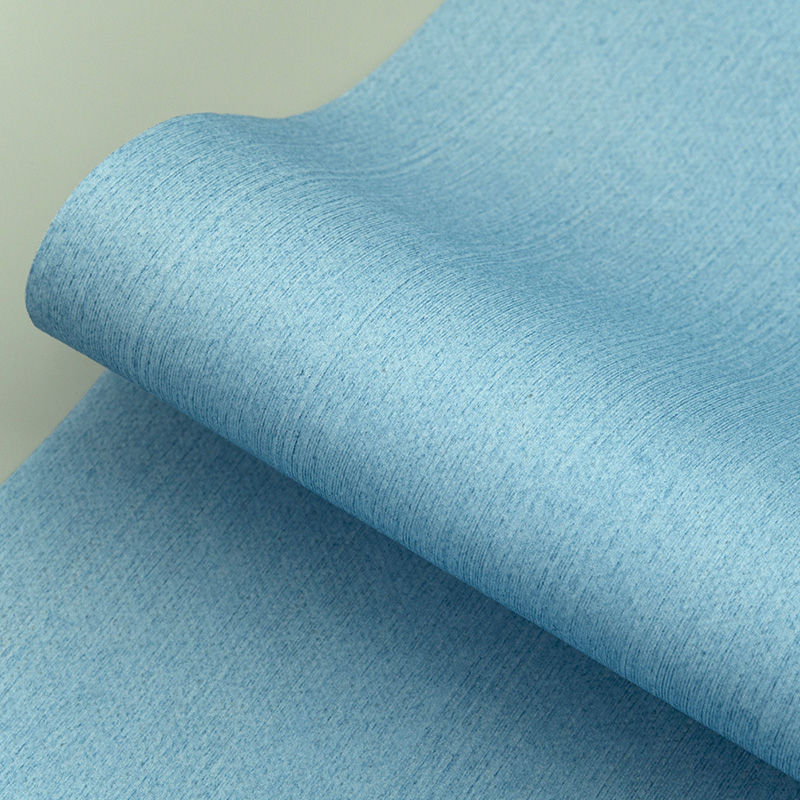

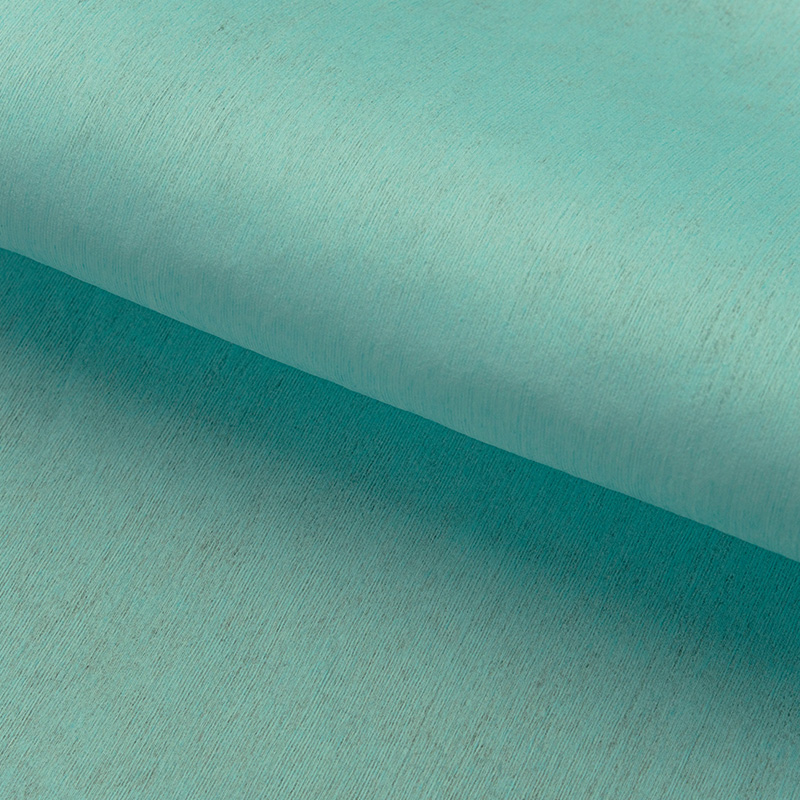

| Color | Blue, green, red etc based on customization |

Features: No fading, clear lines, Super liquid absorption ability, no fiber falling offduring use, to ensure the qualityof wiping and efficient removal ofwater stains andoil.

Uses: Mainly used for civilian wiping and beauty industry, lazy rag, disposable bathtowel, foot bath cloth

It can be sold in any way such as raw material or point-break coil

Advantages :

1.Dust-free: No fibers will fall off during use, and no chips will fall off. It is suitable for food-grade materials and avoids secondary pollution.

2.Soft material: Does not produce any scratches, protects the surface of the cleaning object and the user’s skin.

3.Powerful adsorption function: more than 4 times faster than ordinary cotton rags, quickly removes water stains and oil stains, and saves water resources.

4.Resistant to dissolution when used wet: strong and durable, suitable for washing dishes, wiping range hoods, cleaning desktops, etc. to avoid bacterial cross-infection.

5.No static electricity when used dry: suitable for cleaning and tidying up the environment to avoid static interference.

6.Green, environmentally friendly and degradable: meets environmental protection requirements, is environmentally friendly, and provides clean, hygienic and environmentally friendly solutions.

Application Fields:

Plain PP wood pulp non woven fabric has many advantages, including dust-free, soft material, strong adsorption function, anti-dissolution when wet, no static electricity when dry, and green and environmentally friendly and degradable. These properties make it an ideal cleaning material, especially for kitchen life, providing a clean, hygienic and environmentally friendly solution.

1.Industrial wiping: Suitable for wiping cloth needs in the electronics industry, spraying technology, printing industry, mechanical processing and other fields.

2.Civilian wiping: It can be used for civilian cleaning such as wet wipes, compressed towels, kitchen dry wipes, etc.

3.Medical and health care: suitable for medical and health purposes such as surgical gowns, surgical caps, medical sheets, pillowcases, tablecloths, and medical gauze.

Characteristics of Production Process:

1. Flexible entanglement: high-pressure water flow entangles the fibers without damaging the original characteristics and maintaining fiber properties.

2. The appearance is close to traditional textiles: no adhesive is needed, and the appearance is closer to traditional textiles.

3. High strength and low lint: It has high strength and durability.

4. High hygroscopicity and rapid moisture absorption: Tightly entangled fibers have good moisture absorption and rapid moisture absorption capabilities.

5. Good breathability: conducive to air circulation and humidity regulation.

6. Soft and comfortable: soft to the touch, good drape, and comfortable to wear.

7. Variable appearance: A variety of appearances and patterns can be achieved.

8. Washability: No need for adhesive reinforcement and good washability.

However, the production process also has some shortcomings, such as long production processes, large floor space, complex equipment, high water quality requirements, and high energy consumption.

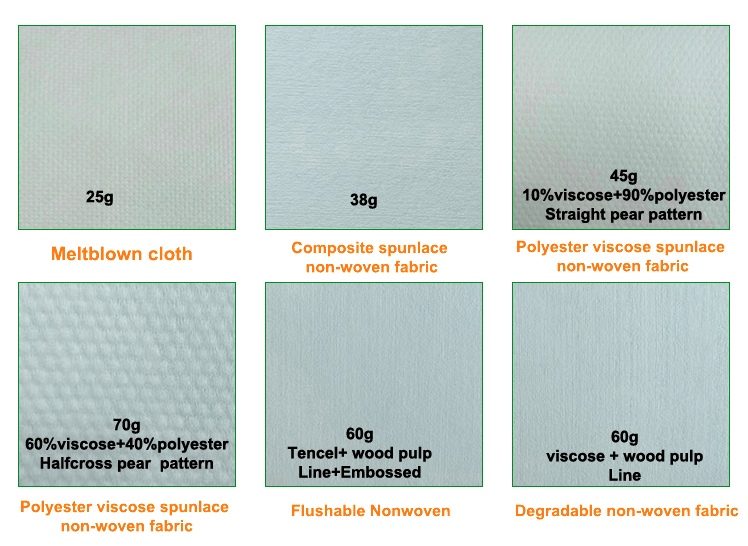

Other Material of Spunlace Nonwoven Fabric For Your Choose:

More Details Please massage us!

We are proud to offer OEM/ODM support and uphold strict quality control standards with ISO, GMP, BSCI, and SGS certifications. Our products are available for both retailers and wholesalers, and we provide comprehensive one-stop service!

Why Choose us?

1. We have passed many qualification certifications: ISO 9001:2015, ISO 13485:2016, FSC, CE, SGS, FDA, CMA&CNAS, ANVISA, NQA, etc.

2. From 2017 to 2022, Yunge medical products have been exported to 100+ countries and regions in America, Europe, Asia, Africa and Oceania, and are providing practical products and quality services to 5,000+customers around the world.

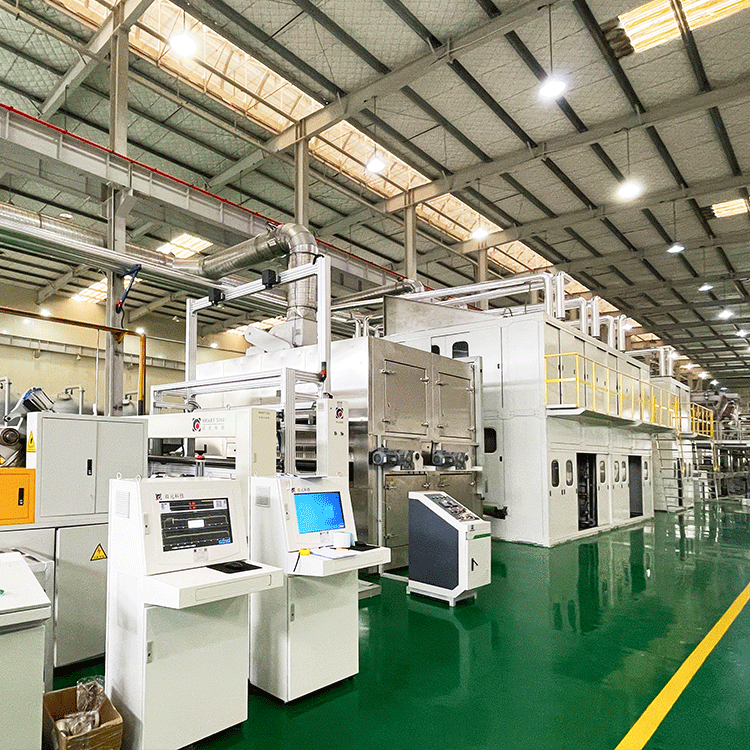

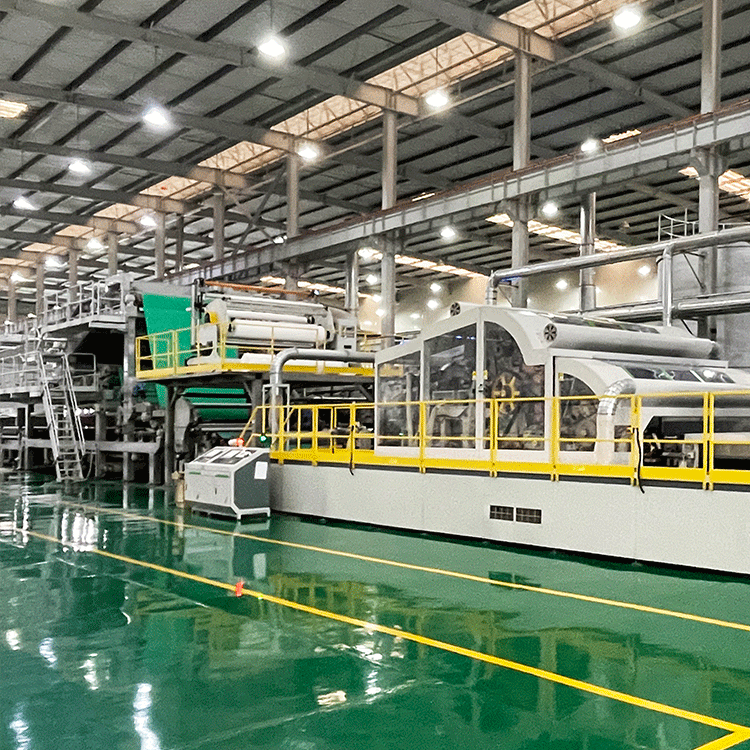

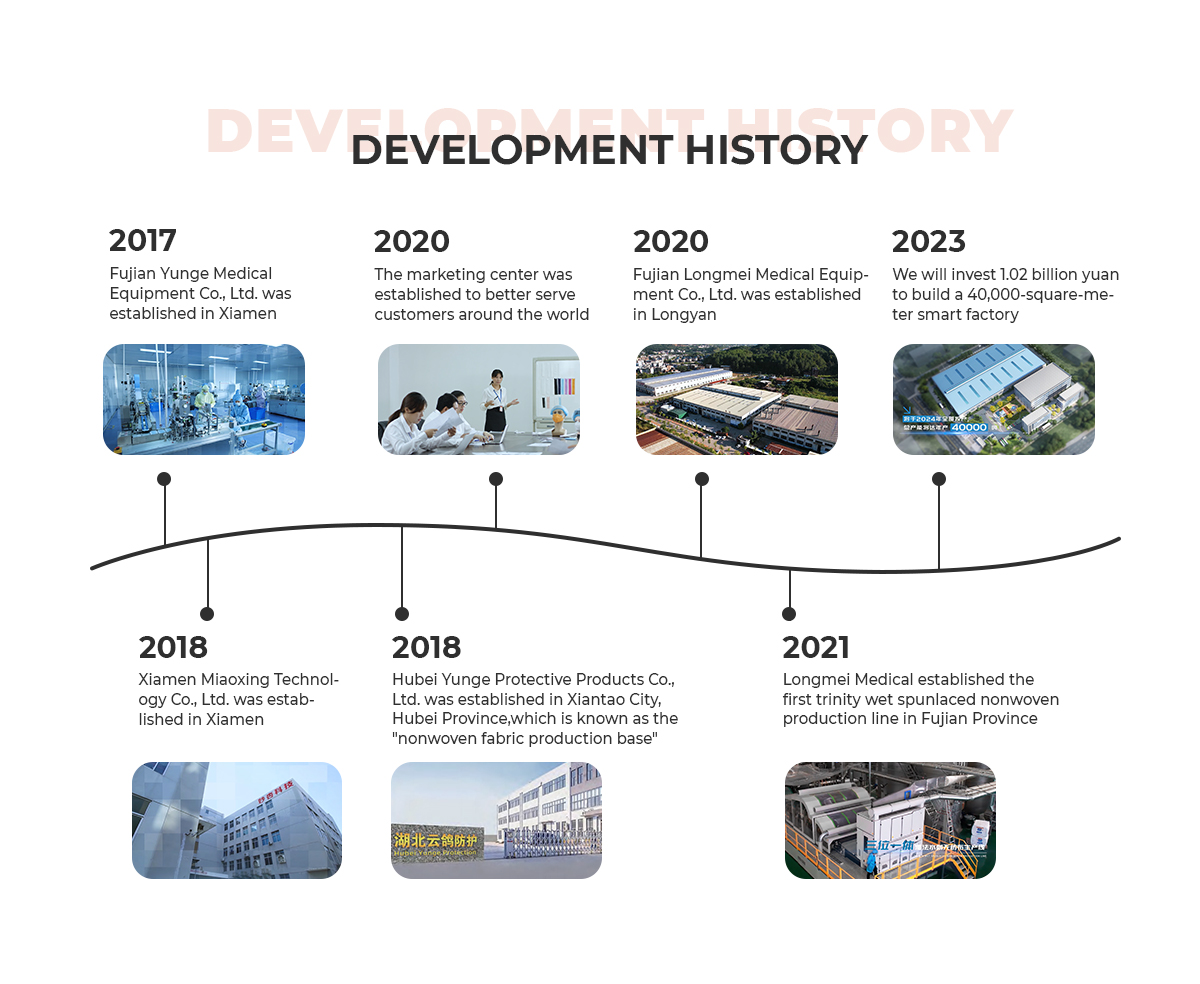

3. Since 2017, in order to provide better products and services to customers around the world, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

4.150,000 square meters workshop can produce 40,000 tons of spunlaced nonwovens and 1 billion+of medical protection products every year;

5.20000 square meters logistics transit center, automatic management system, so that every link of logistics is orderly.

6. Professional quality inspection laboratory can carry out 21 inspection items of spunlaced nonwovens and various professional quality inspection items of a full range of medical protective articles.

7. 100,000-level cleanliness purification workshop

8. Spunlaced nonwovens are recycled in production to realize zero sewage discharge, and the whole process of "one-stop" and "one-button" automatic production is adopted. The whole process of the production line from feeding and cleaning to carding, spunlace, drying and winding is fully automatic.

In order to provide better products and services to customers around the world, since 2017, we have set up four production bases: Fujian Yunge Medical, Fujian Longmei Medical, Xiamen Miaoxing Technology and Hubei Yunge Protection.

Leave Your Message:

-

Diamond Pattern Spunlace Non Woven Fabric Wipes

-

Spunlace non woven fabric for beauty care used

-

spunlace nonwoven fabric jumbo roll for industr...

-

Blue Non Woven Fabric Rolls Industrial Wipes

-

Multi-Colored Woodpulp Polyester Non Woven Fabr...

-

Different Pattern Non Woven Fabric Rolls

-

Oil Stain Cleaning Industrial Non Woven Fabric ...